Building thermography

What is thermography, what is included and in what environmental parameters is thermography useful?

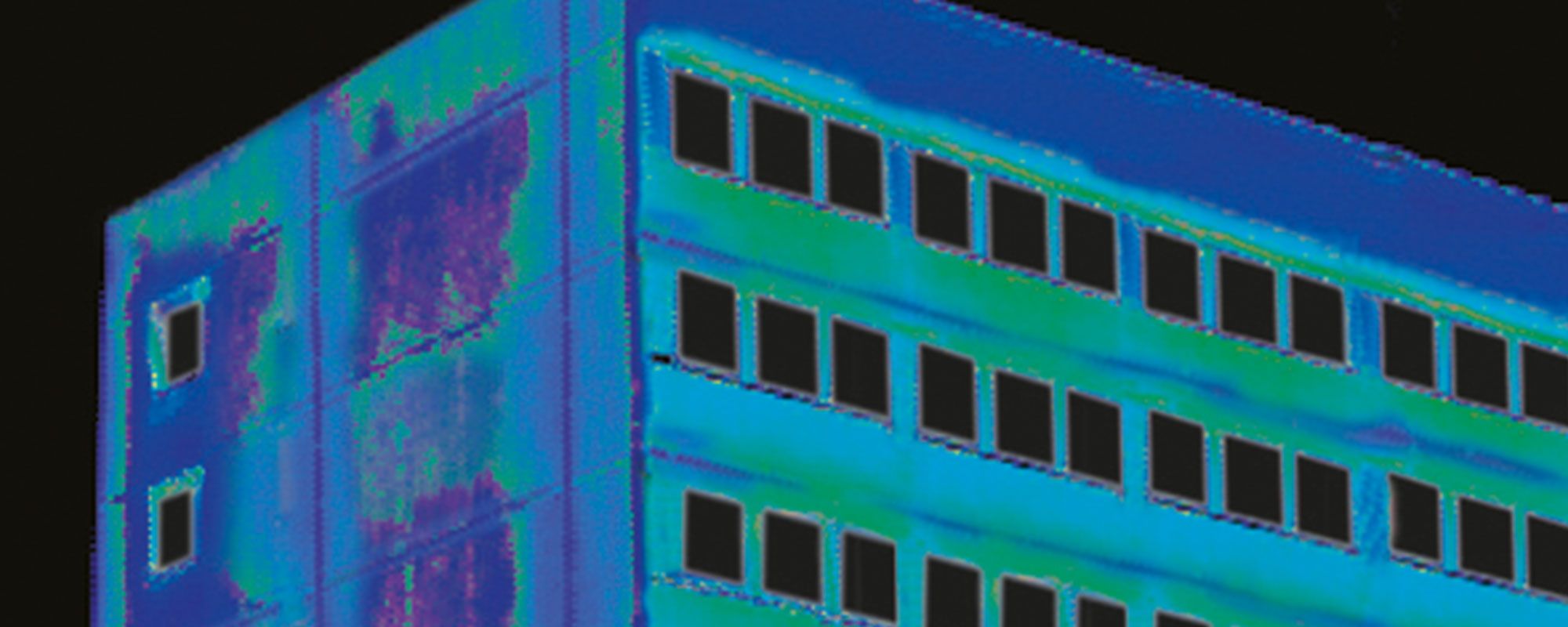

During thermography, the radiated surface temperatures are recorded. The camera can detect small temperature changes e.g. from a wall surface where a window is installed, and present these changes in various colours.

On the one hand, it is important that these differences are correspondingly large but on the other hand it is necessary that the temperatures are always recorded at a 90° angle to the surface to avoid recording false results.

The following information is of particular importance:

- External temperature for the object

- Internal temperatures of each room

- Weather conditions (rain / snow etc.)

- Time the data was collected

- Type of camera

- Emission level

- Date the data was collected

A prerequisite for taking the measurements is that the difference between the external air temperature and the surface temperature of the object to be measured is sufficient. This should be a difference of 15° Kelvin. Measurements are only useful if the interior rooms are heated. This must be the same across the entire building where possible and be carried out and maintained for 24 hours before the measurements are recorded.

The following must be present in order to precisely document the measurements:

- Recording of the overall view digitally and normally in the daylight

- Thermographic recording of the overall view

- Detailed, thermographic view with precise temperature identification

The output image then displays the following information:

- Type of camera

- Date the data was collected

- Time the data was collected

- Emission level

- Image number (automatically assigned by the camera)

- Temperature gradient

- Highest temperature recorded

There are numerous possibilities for error! It is important to note that the colours of the surfaces shown are not the decisive element (red = poor, green = good), but instead the surface temperatures shown and, in particular, the differences. The 1-2 degree differences in the data recorded for windows are for technical reasons related to heat flux, e.g. for glass spacers. This is not a fault but a technical feature.

Although the left image shows many red areas, this does not indicate any faults. The red areas in the right-hand image highlight faults, or rather areas of strong heat loss.